Protecting neighbors from e-drums with Sylomer

I play electronic drums in a multi-store apartment building. In the first 5 minutes after I received the drum kit, assembled it and started playing, the lady from the apartment below was furiously slamming on my entrance door and it became apparent that the problem of soundproofing the drum kit was very much integral to the whole “me-being-a-drummer” project.

The problemSection titled The%20problem

The main source of noise from playing the drum kit for the neighbors underneath is the impact noise which is a form of structure-borne sound, which means a vibration that is transmitted by the structural components of the building itself: floor, walls, etc. There is another form of noise in the context of soundproofing inside buildings - air-borne sound noise. You should consider it too if the natural sound isolation of the building is not good enough, i.e. you can hear your neighbors shouting or even speaking. Measures for absorbing the air-borne noise from the drum kit in an apartment are different: usage of sound panels, acoustic curtains, etc. I will not focus on them here and instead explain how to build a drum riser platform with the use of Sylomer.

SylomerSection titled Sylomer

Sylomer is a product of an Austrian company called Getzner which specializes in vibration isolation and operates for more than 50 years. The material looks like a colored sponge, but is used in a wide variety of contexts: from isolating railways and heavy machinery to making apartments with rooms-inside-a-rooms.

Sylomer comes in 5m rolls of 1.5m width, but local stores and companies specializing in soundproofing and vibration isolation may sell it to you in thin stripes. I ordered 10cm wide stripe of the Sylomer:

CalculationsSection titled Calculations

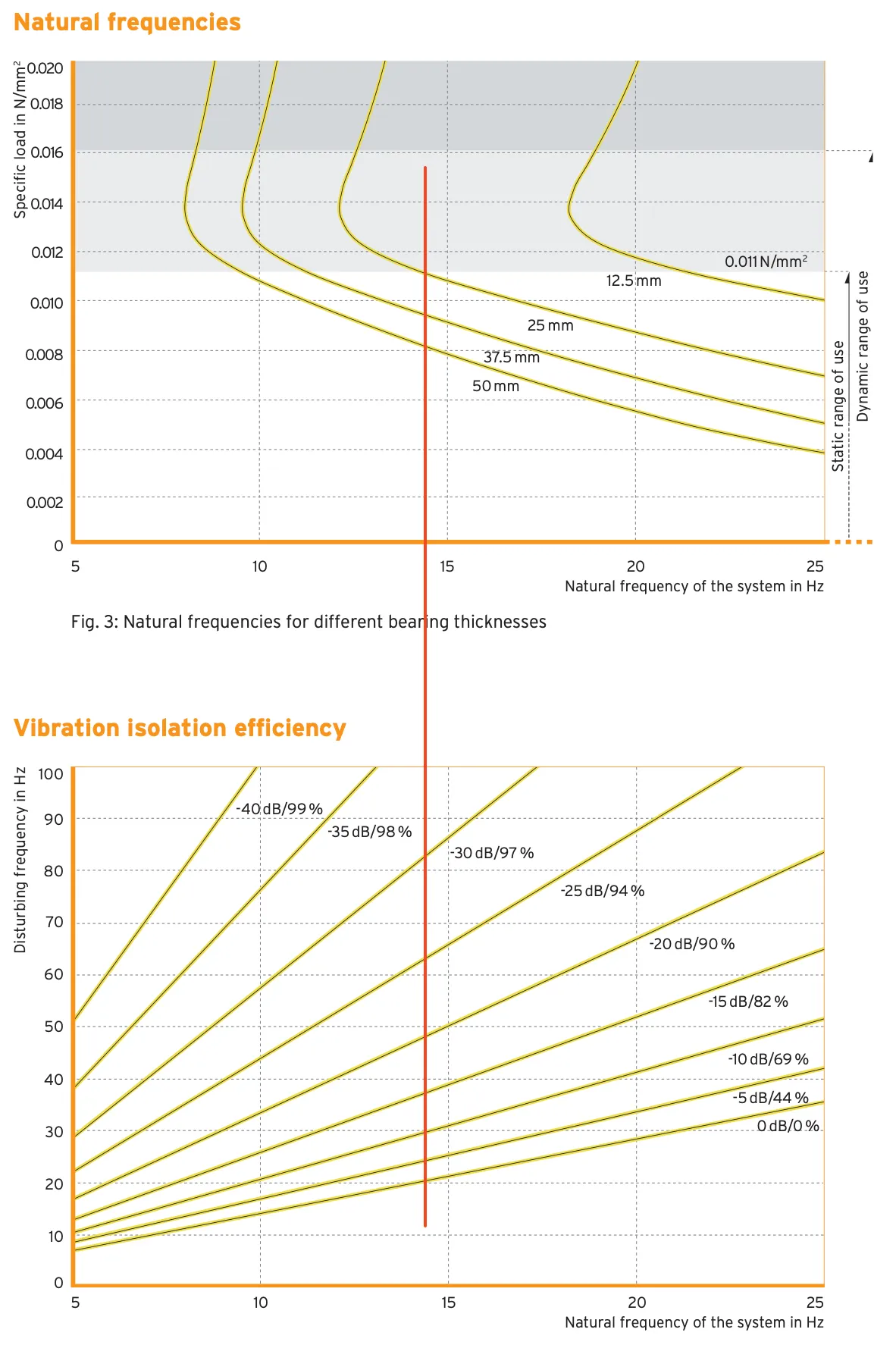

The data sheet for the Sylomer SR11 may look intimidating to somebody with zero prior knowledge of industrial engineering, like me. But with the support of Google, YouTube and chatGPT I figured it out.

Sylomer must be properly loaded to absorb vibrations efficiently. The data sheet specifies a static range of use of

up to

Sylomer also comes in two variants: 25mm thick and 12.5mm thick. The thicker Sylomer is, the lower the frequency it can attenuate. But if it’s too thick, it will “bulge” too much when transferring weight, like playing the bass drum or just moving around on the stool. I chose 25mm thick as a good middle ground. That’s how much attenuation can be expected from it:

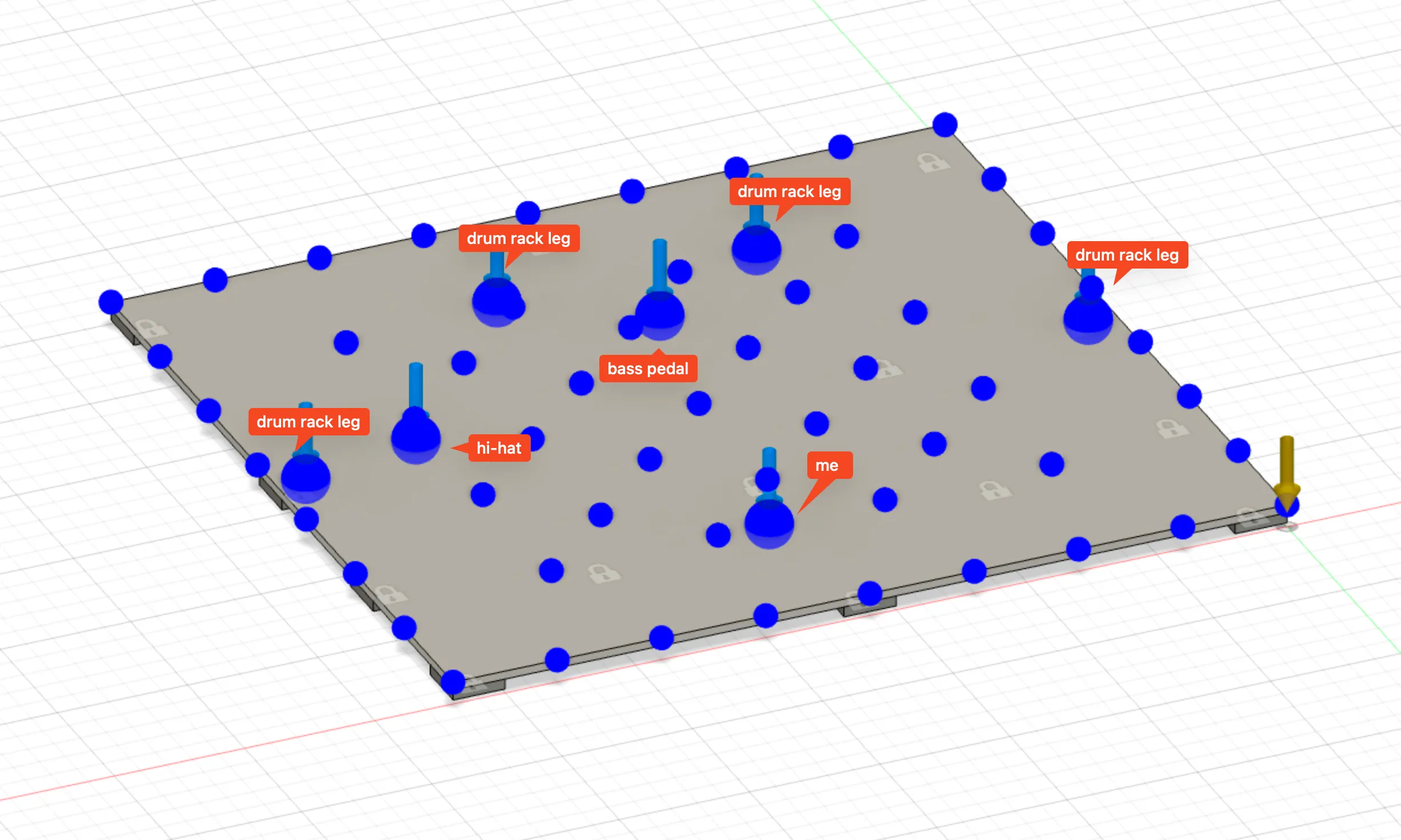

To calculate how much Sylomer to use the weight of all of the

objects on top of the Sylomer blocks must be known: the drummer, the drum kit and the board itself.

Given that

where

For example, the weight of myself, the drum kit and the platform I am using is

First attemptSection titled First%20attempt

Actually, at first, I incorrectly assumed that I must “aim” right at the center of that “dynamic range of use”

between

The Sylomer deformed to 15mm in size from the initial 25mm.

There is a graph in the data sheet that shows that if loaded properly, the deformation must be

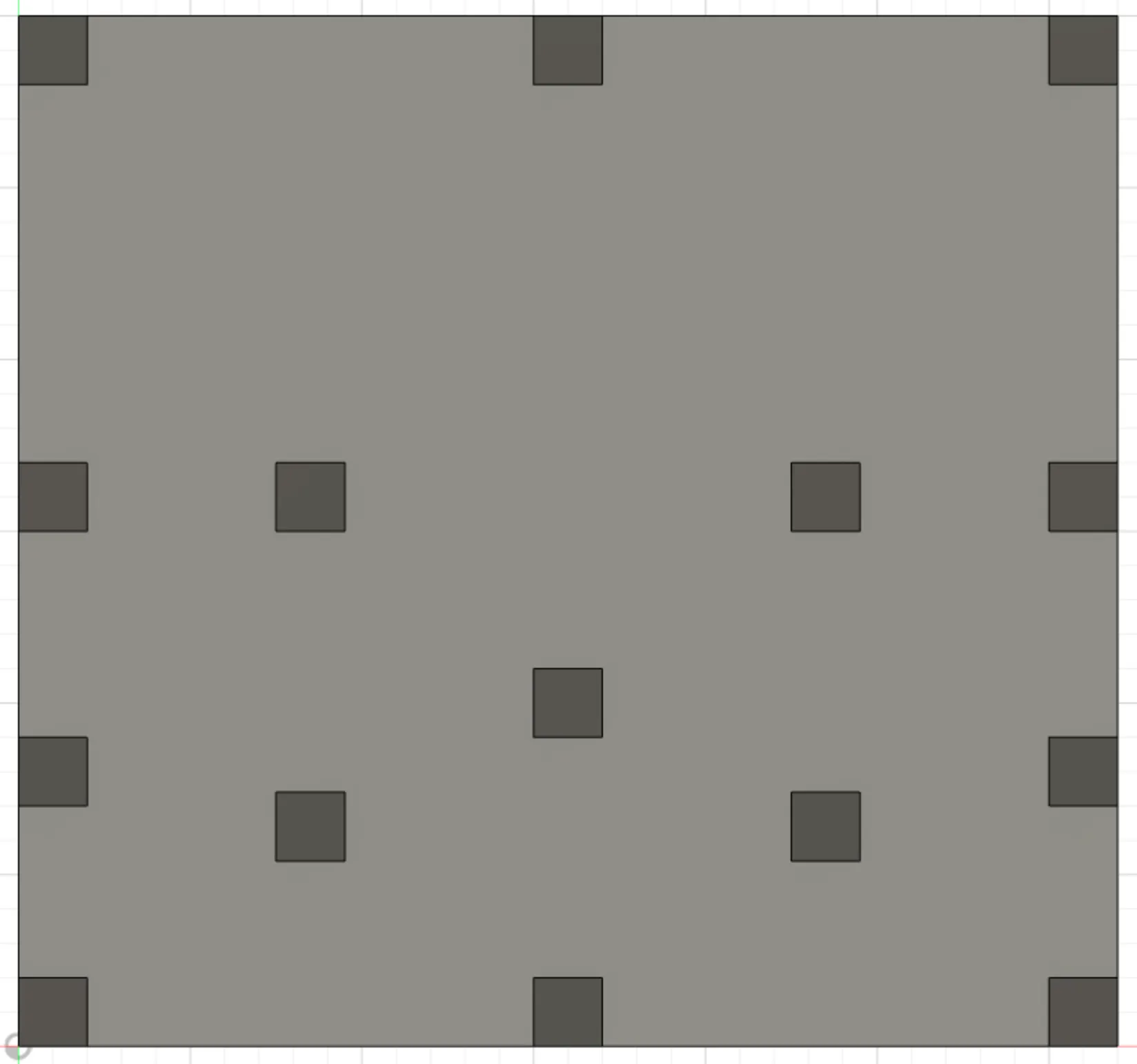

Also, the arrangement of blocks was chosen rather arbitrarily, I basically eyeballed it:

But this is crucial, as not considering where the center of mass is, also results in overloading and underloading of different blocks of Sylomer and them not attenuating noise properly. After I initially made the riser, my neighbors still reported that the noise from playing was disturbing.

The fixSection titled The%20fix

So I increased the number of Sylomer blocks to 15 and used Fusion360 to simulate the static load of me and the drum kit on the board.

And arrived at this arrangement which seems to evenly load all the blocks of Sylomer.

The board doesn’t wiggle too much and most importantly - neighbors have stopped complaining!

Board materialSection titled Board%20material

I am using a simple 16mm thick 1.5m x 1.4m particle board.

And I have found it is more than enough.

Various other blogs and YouTube videos recommend getting “at least 20mm thick MDF” - but that looks like overkill.

And I am not sure what purpose such a thick board would serve.

The particle board is strong enough not to brake if I stand on one part of it and Sylomer starts to bulge.

It certainly flexes more than MDF, but so what? And MDF or OSB even of the same thickness would weigh so much more.

This board already weighs 26 kg! I can barely lift it, because of its weight and size.

You can order particle board already laminated and choose a surface that will match your interior!

One more recommendation is to choose a high-density particle board of at least

Final resultSection titled Final%20result